Confluence Electrical Solutions is committed to SAFETY

SAFETY CULTURE

It is our primary objective to prevent all injuries by providing and maintaining the safest possible working conditions for all of our employees and subcontractors regardless of where we are in the world.

The level of excellence and effectiveness established through our safety management culture is critical to the success of our projects and bringing value to our clients. At CES, we believe there are four essential, consistent characteristics of safety excellence:

Management Leadership & Commitment

Project Team Safety Engagement & Training Program

Safety Compliance Measurements

Safety Improvement Process

Crisis Management

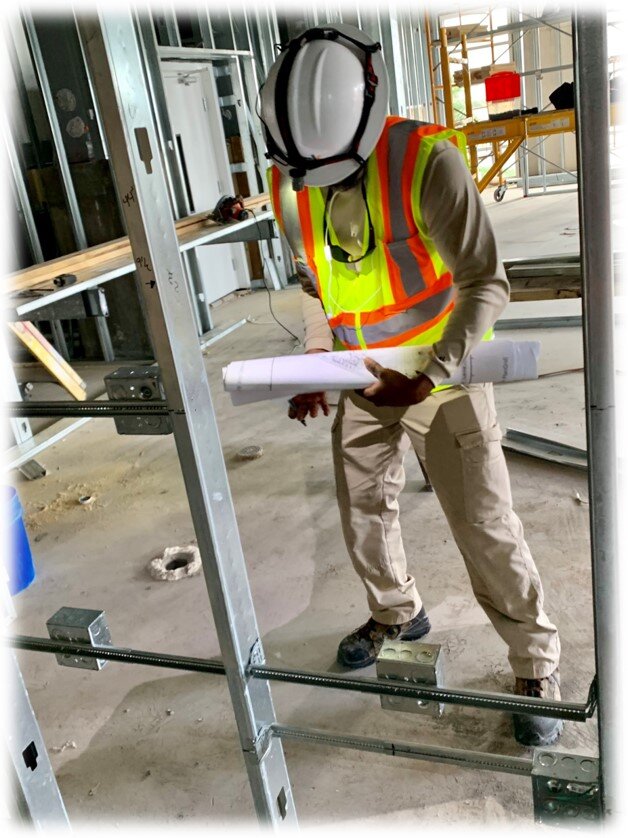

SAFETY IS OUR FOUNDATION

As a core business value, safety is at the forefront of our operational best-practices and communications. This central principle continues to produce world class safety performance. We understand that safety must permeate all levels of the construction process from our leadership, down through our management ranks, and especially to our project teams and field personnel. As leaders in the construction industry, Confluence Electrical Solutions is committed to SAFETY as a core business value. All Superintendents, Foreman and Sub-Foreman receive the following training:

OSHA 30 Continuing Education

Red Cross CPR/AED Certification

Electrical Jobsite Safety

Work on new and existing energized (hot) electrical circuits is prohibited until all power is shut off and grounds are attached.

An effective Lockout/Tagout system is in place.

Frayed, damaged or worn electrical cords or cables are promptly replaced.

All extension cords have grounding prongs.

Protect flexible cords and cables from damage. Sharp corners and projections should be avoided.

Use extension cord sets used with portable electric tools and appliances that are the three-wire type and designed for hard or extra-hard service. (Look for some of the following letters imprinted on the casing: S, ST, SO, STO.)

All electrical tools and equipment are maintained in safe condition and checked regularly for defects and taken out of service if a defect is found.

Do not bypass any protective system or device designed to protect employees from contact with electrical energy.

Overhead electrical power lines are located and identified.

Ensure that ladders, scaffolds, equipment or materials never come within 10 feet of electrical power lines.

All electrical tools must be properly grounded unless they are of the double insulated type.

Multiple plug adapters are prohibited.

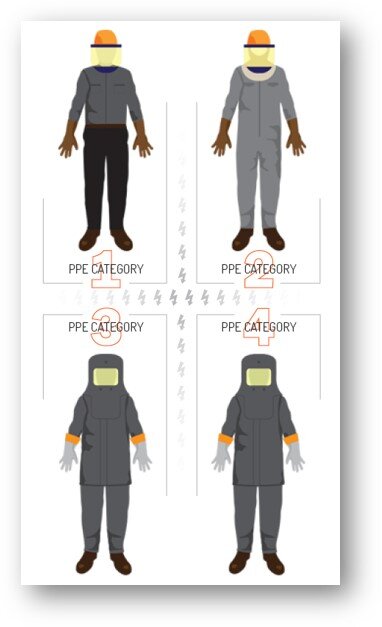

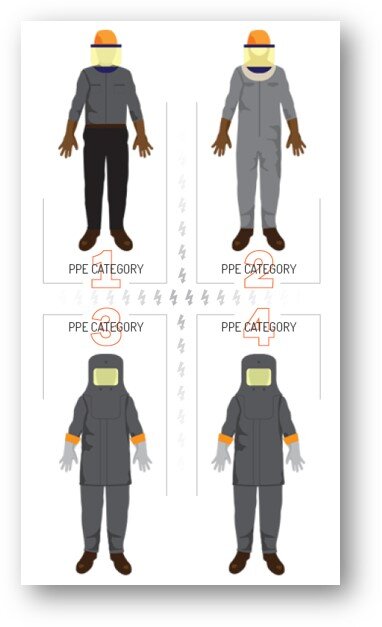

This video is meant to help promote safety awareness by sharing my experience before during and after an electrical "Arc Flash" accident. I'm not offering ‘arc flash’ education or providing safety rules or guidelines. I am simply telling what could happen if you don't follow your safety procedures.